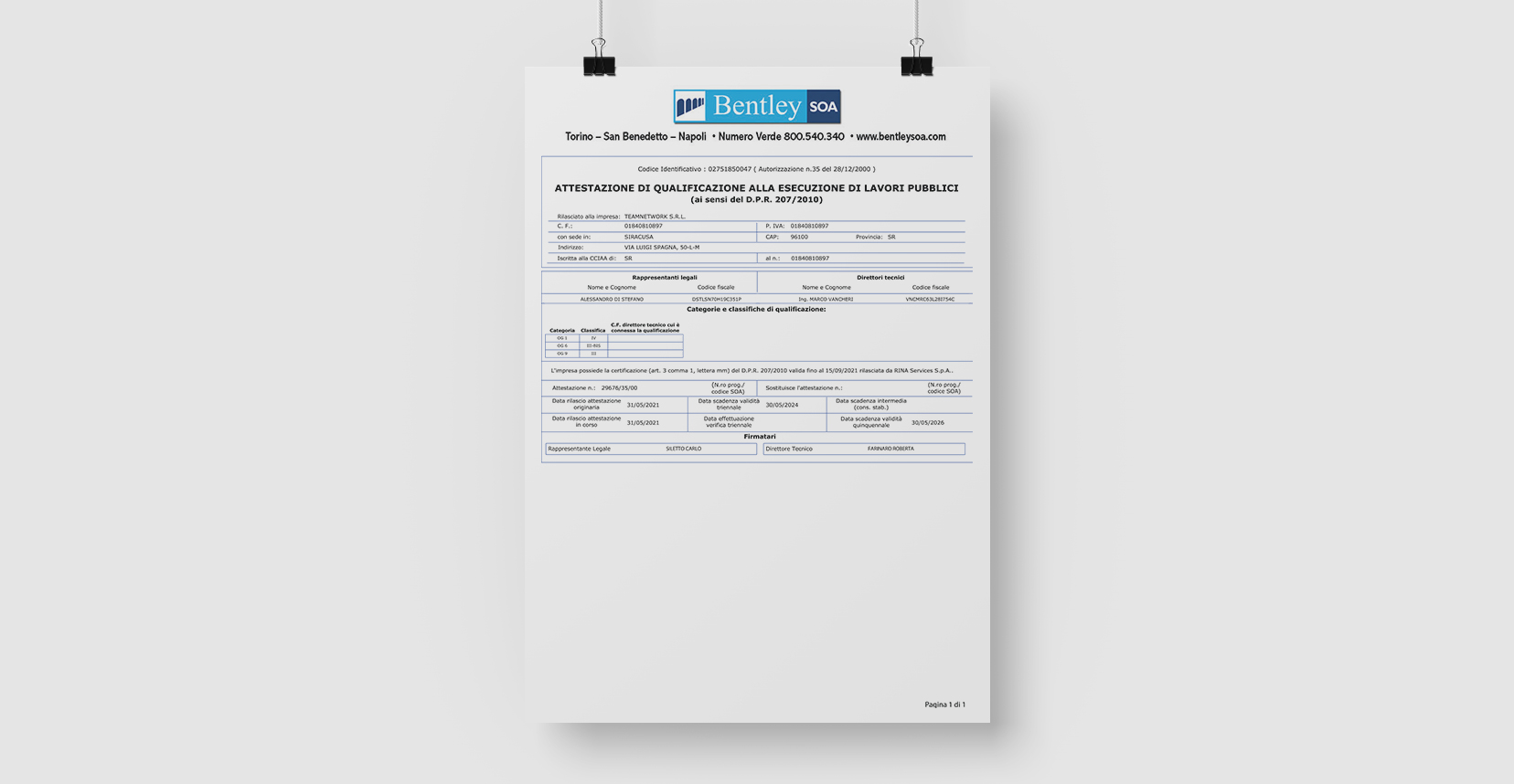

The project includes the plant and final engineering, the construction and assembly of an additional line for the extraction and loading of the bulk cement placed laterally with respect to the two existing silos. Before the work, the cement was loaded on to trucks in the two loading tracks under the silos – built by Contimpianti in 2005 and fitted with 8 + 8 mobile trolleys.

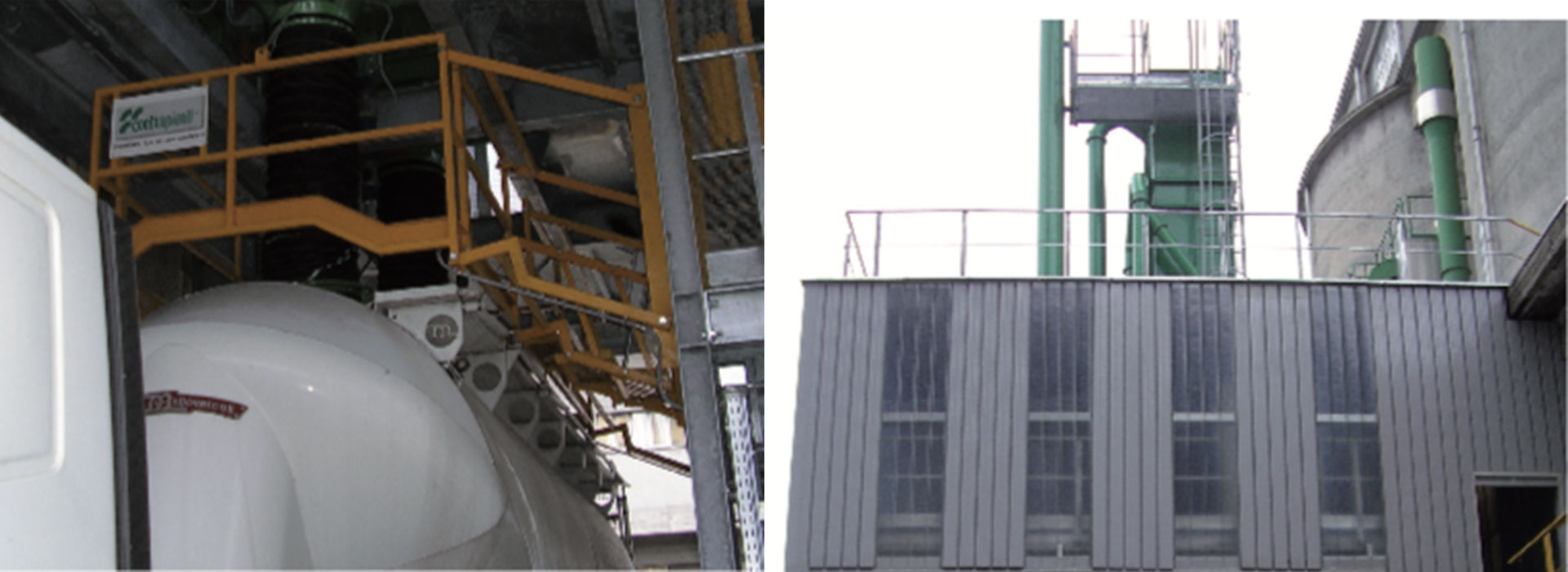

To meet the customer’s new requirements, Contimpianti created a supplementary loading track with new extraction on the lateral concrete wall of one of the two silos. With the help of airslides, the material from the bottom of the silo is conveyed outside and through airslides to the two trucks for loading the loose cement on to lorries. The capacity guaranteed for each trolley is 200 ton/h. The dust collection of the plant is guaranteed by a Contimpianti bag filter with a capacity of 6000 m3/h.

The plant has a service level for the drivers doing the loading operations (self-service). Thanks to an automated mobile protection system, the drivers can access the top of the truck directly to open and close the hatches and to supervise the loading phase in conditions of complete safety.

In order to guarantee that the plant confirms to the “Machinery Directive 2006/42 CE”, Contimpianti, appointed by Holcim (Italia) S.p.A., has taken on the position of final constructor, involving the client’s technicians and the suppliers of the automation and electrical circuits in the process of risk analysis integrated with the design.

The solution proposed by Contimpianti has the twofold advantage of meeting, on the one hand, the new conditions of performance with work which, by not upsetting the existing structure of the plant, makes the most of the spaces and potential and, on the other, guarantees that the operators can work in safety.