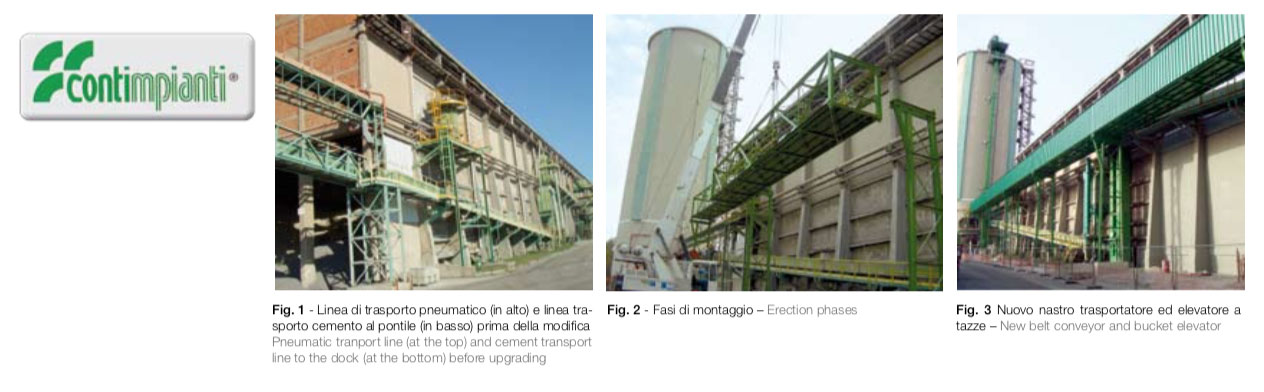

Thanks to the coopera- tion of all Teamnetwork branches, in October 2008 Contimpianti S.p.A. completed successfully for Buzzi Unicem plant in Augusta (Sicily – south of Italy) the project for increas- ing the loading capacity of cement bulk transport on ships and replacement of the old pneumatic trans- port system with a new mechanical one.

The main target of the upgrading was adapting the existing bulk loading cement transport installations in order to drastically reduce the overall power consumption, increase its potentiality as well as optimise the throughput of cement by exploitation of the available space with the fewest number of grinding changes. In addition, the client required to increase the cement loading capacity onto the ships, from the previous 300 tons/h up to 550 tons/h and that to satisfy the new market needs and decrease ships waiting time at loading dock. Shortly, Contimpianti project considered the replacement of the existing pneumatic transport system with a mechanical one having hourly capacity of 250 tons/h. The new mechanical system is made up of a new airslide, a rubber belt conveyor and a rubber belt bucket elevator. The installation of the new bucket elevator allowed the realization of a more efficient shipping line from the storage silo to the loading dock with increased transport capacity of 550 tons/h. To guarantee a low dust emission level into the atmosphere, Contimpianti has also designed the complete dedusting facilities. Specifically, a bag filter has been mounted serving both the elevator and the belt unloading point. After upgrading, the average specific consumption (calculated on the absorbed power) is 0,6 kWh/ton versus the previous 5,80 kWh/ton of the old pneumatic transport system, resulting in a power saving of 5,2 kWh/t.